The Correct Way To Solder Braided Lead

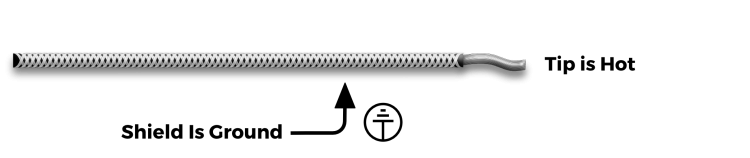

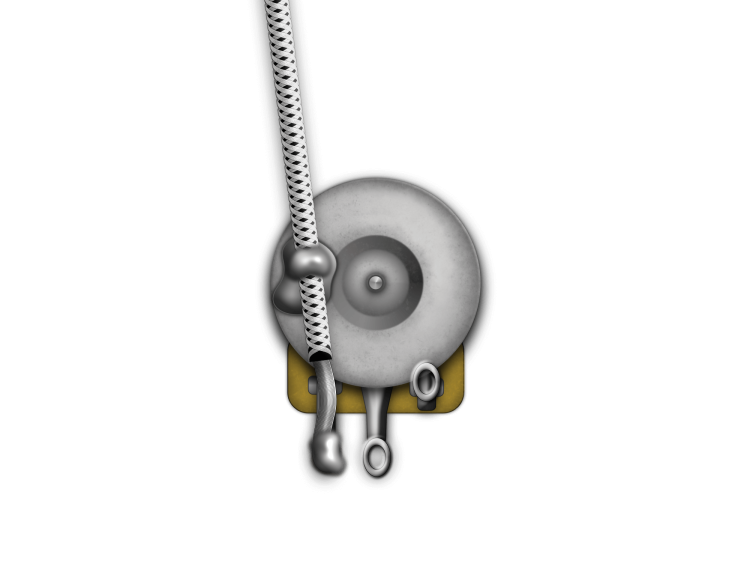

Working with Gibson Braided Lead can be a bit challenging at first, but it doesn’t have to be! This lead is a durable and straightforward style used for guitar pickups. It consists of a stranded hot wire, which is surrounded by cloth insulation and covered by metallic braiding. Here’s a brief overview:

The braiding (or shield) is always grounded, while the center wire is hot. Installing this lead involves soldering the braiding to the back of the pot to ground it, and connecting the center wire to a lug on the pot. In a Les Paul example, here’s how you would solder the pickup to the pot:

Grounding the braiding can be tricky, so we’ve compiled some tips to help you successfully manage your Braided Lead connections.

The Problem:

Both the braiding of the lead and the casing of the pot require a significant amount of heat to create a solid connection. However, applying too much heat can overcook the connection, potentially damaging the pot or burning the cloth insulation, which may result in the inner wire shorting out to ground.

Solution: Pre-tin your connections

The key to a successful connection is to pre-tin both ends before soldering. Pre-tinning allows you to connect the wire to the pot without the risk of overheating either component. Here are the basic steps to follow:

- Apply solder to the back of the pot

- Apply solder to the braiding

- Use your soldering pencil to then solder the two together

By following these steps, you can ensure a reliable and safe connection!